The Chicago Screw: A Comprehensive Exploration

Introduction

The Chicago screw, also known as a binding post or screw post, is an innovative and practical fastener that has played a significant role in binding materials together, primarily in the publishing and stationery industries. Its unique design offers a range of applications, from securing loose-leaf pages to forming functional components in various industries. This article aims to provide a thorough examination of the Chicago screw, exploring its history, design, applications, manufacturing process, and its significance in modern times.

## Historical Background

### Early Innovations

The book binding screw owes its name to its origins in the bustling city of Chicago during the late 19th century. Initially designed to bind ledgers and accounting books, the screw was a significant advancement over traditional methods of binding that often proved cumbersome and less durable. Its introduction coincided with the rapid industrialization of America, where businesses and organizations sought more efficient ways to keep their records organized.

### The Evolution of Binding Techniques

Before the advent of the Chicago screw, various binding methods were in use, including stitch binding, glue binding, and more primitive forms of fastening. Each had its limitations, such as durability, ease of use, and flexibility in adding or removing pages. The Chicago screw revolutionized bookbinding and personal organization tools, providing a robust yet flexible mechanism that allowed for easy assembly and disassembly.

## Design and Structure of the Chicago Screw

### Components

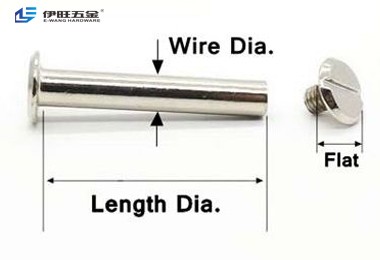

A typical Chicago screw consists of two primary components: a post and a screw. The post often has a smooth shaft that fits neatly into a hole in the material being bound, while the screw has a head that allows for turning and tightening. When assembled, the screw penetrates the post, creating a secure hold that can be adjusted or loosened as needed.

### Material Considerations

Chicago screws are commonly manufactured from metals such as brass, stainless steel, or aluminum, though they can also be found in plastic versions for lighter applications. The choice of material depends on the intended use, durability requirements, and aesthetic considerations. For example, brass is often chosen for its corrosion resistance and classic appearance, making it ideal for high-end publications and personal stationery.

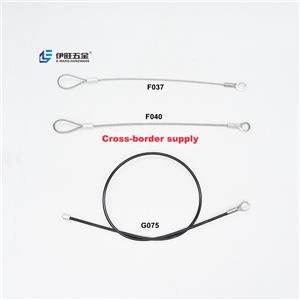

### Sizes and Variations

Chicago screws come in various sizes and lengths, accommodating different thicknesses of materials. Standard sizes range from a quarter-inch diameter to larger variants used for thicker books or portfolios. Additionally, variations such as decorative heads or colored finishes allow for customization, making them suitable for a range of applications from industrial to artisanal.

## Applications of Chicago Screws

### Bookbinding and Stationery

The most common application of Chicago screws is in the binding of books, particularly loose-leaf binders and reports. They allow for easy page turnover and the addition of new materials without damage to the existing pages. This adaptability makes them a favorite in educational settings, where students and educators require frequent updates to their materials.

### Art and Craft

In the art world, Chicago screws are often used to bind sketches, portfolios, and other creative works. Artists appreciate their ability to maintain a clean finish while still allowing for easy modifications. Customizable options further enhance their appeal, offering a stylish way to present artwork or portfolios.

### Industrial and Mechanical Uses

Chicago screws have found their way into various industrial applications, including assembly lines, machinery, and equipment maintenance. Their robust design is crucial in environments where tools and machinery must be secured reliably. Their ability to endure stress and strain makes them a vital component in mechanical engineering.

### Electronics and Gadgets

In the electronics industry, Chicago screws are often used to secure components within casings and enclosures. They allow for easy assembly and disassembly of devices for upgrades and repairs, critical in a fast-paced technological landscape where hardware may need frequent updates.

## Manufacturing Process

### Material Selection

The manufacturing of Chicago screws begins with material selection. As mentioned earlier, metals and plastics are common choices, with each material catering to specific requirements like strength, weight, and cost.

### Machining and Shaping

Once the material is selected, the manufacturing process involves several steps:

1. **Cutting**: Raw materials are cut into pieces that will be shaped into screw posts and screws.

2. **Shaping**: The cut materials are then formed into the desired shape, often using processes like extrusion or machining for precision.

3. **Drilling**: Holes for the screw threads and the shaft are drilled into the posts, allowing for the screws to fit snugly.

4. **Finishing**: The screws undergo various finishing processes, such as polishing, coating, or plating, to enhance their appearance and protect against corrosion.

### Quality Control

Quality control is critical throughout the manufacturing process. Each batch of screws is tested for strength, fitting, and visual appeal, ensuring that they meet industry standards. This emphasis on quality assures end-users of the reliability and functionality of the screws.

## Advantages of Using Chicago Screws

### Versatility

One of the most significant advantages of Chicago screws is their versatility. They can accommodate a variety of materials, including paper, plastic, and metal, making them suitable for numerous applications. Whether in arts and crafts, mechanical assembly, or everyday bookbinding, Chicago screws can be effectively utilized.

### Durability

Constructed from strong materials, Chicago screws provide durable fastening solutions that can withstand wear and tear. Their ability to be securely tightened means that they maintain their hold over time, which is particularly important in settings where items are frequently handled or moved.

### Ease of Use

Chicago screws are user-friendly, allowing for straightforward assembly and disassembly. Users can simply screw and unscrew the fasteners without needing special tools, making them an excellent choice for those who require flexibility in their projects, such as students or artists.

### Aesthetic Appeal

With options for decorative designs and finishes, Chicago screws also serve an aesthetic purpose. In presentations and artistic displays, the appearance of the fasteners can enhance the overall quality of the presentation.

## Challenges and Limitations

### Cost

While Chicago screws are affordable in many contexts, they might be more expensive than simpler binding methods, especially for large-scale applications. For businesses working on tight budgets, this cost can be a concern.

### Size Limitations

Although variations exist, Chicago screws generally have size limits that may affect their application in specific contexts. For extremely thick materials or specialized uses, other fastening methods might be more versatile.

### Accessibility

In some cases, the availability of various sizes and materials of Chicago screws may be limited in certain regions or markets, making it challenging for users to procure the specific fasteners they need.

## The Future of Chicago Screws

### Innovations in Design

As industries continue to evolve, so too does the Chicago screw. Manufacturers are exploring new materials and designs to improve the function and aesthetics of these fasteners. Innovations such as self-locking screws or environmentally friendly materials are on the rise, catering to modern demands for sustainability.

### Digital Integration

With the rise of digital technology, traditional applications of the Chicago screws may be complemented by digital tools. For instance, electronic document management systems may require less physical binding, but the need for organization and binding in specific sectors remains and may lead to a resurgence in demand.

### Sustainable Practices

The push for sustainable practices across industries may also impact the production and use of Chicago screws. Manufacturers are likely to explore renewable materials and recycling methods to reduce waste while still providing functional products.

## Conclusion

The Chicago screw is far more than a simple fastener; it is a multifaceted tool that has evolved alongside the demands of various industries. From its historical roots in bookbinding to its applications in modern manufacturing, design, and art, the Chicago screw demonstrates versatility and a unique capacity for adaptation. As industries continue to innovate, the Chicago screw will likely remain a vital component, reflecting the balance between functionality and aesthetic appeal in an ever-changing world.

As this examination shows, the Chicago screw underscores the ingenuity of design and the importance of effective solutions in binding and fastening needs. Whether enhancing art projects, securing electronic devices, or enabling efficient document management, these simple yet effective fasteners are integral to many creative and industrial processes, assuring their relevance for years to come.